|

|

||||||||||||||||

|

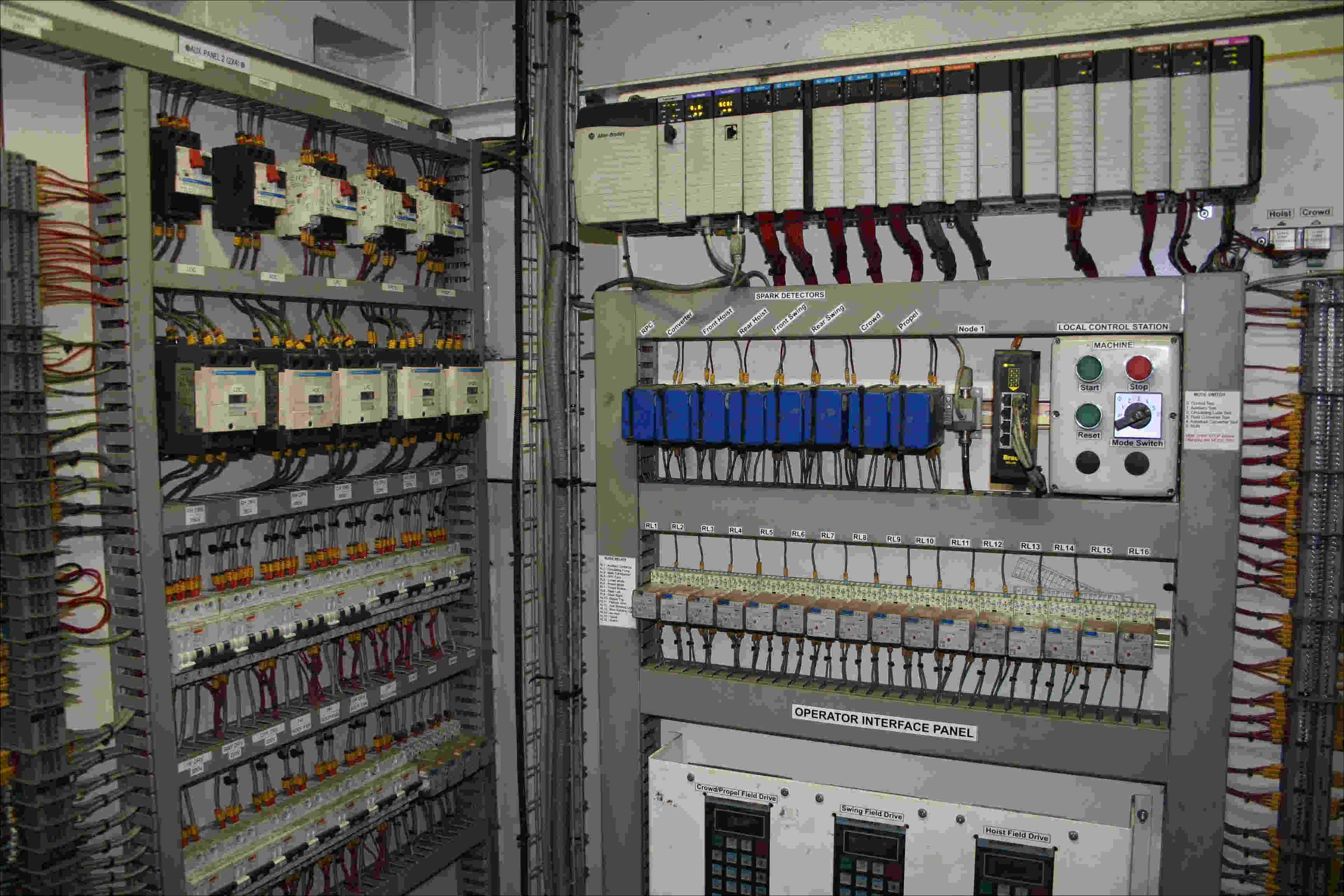

PH2300Mk2 - Oil Cooled Converters replaced by Digital DrivesAn upgrade to bring older machines back to life and to reduce fire risks resulted in the development of the Taurus Drive and Control System for Opencast Machines. It can be adapted to replace any existing drive system be it a MagneTorque, ElectroTorque or Centurion. The Taurus Drive System for Opencast Machine where developed, constructed and commissioned by Ewbank Electrical and Control. It brought together all the experience and innovations that we gained since 1990. The heart of the Taurus Drive System is an Allen-Bradley Controllogics PLC that Communicates via EtherNet and ControlNet to various devices onboard the machines. Machine Status, Alarms, Trips and history are captured and displayed by two Panelview 550 human machine interfaces located in the coop and PLC control room. Allen-Bradley drives provide the power to the armatures and fields of the DC Motors as per instruction received via ControlNet from the PLC. Would you like to see what happens on each and every machine remotely via the internet? The Taurus Drive System and deliver just that. Would you like your system to decide when to park and stop a machine and when not? The Taurus Drive System can. Nothing happens on a machine without pinpoint accuracy that the Taurus Drive System does not allow or capture. The most outstanding part of the Taurus Drive System is that it can be purchased in kit form, assembled by the customer and jointly commissioned. The cost savings is obvious but the most important attribute is that the customer is able to maintain and look after their systems themselves. |

Taurus Console 1

Taurus PLC and Control Gear

Taurus Field Drive Cabinet |

||||||||||||||

Taurus Transfer Cabinet |

Taurus Armature Drive Cabinet |

|||||||||||||||

|

|

|||||||||||||||

Home : About Us : Services : Case Studies : Contact Us

|

||||||||||||||||