|

|

||||||||||||||||

|

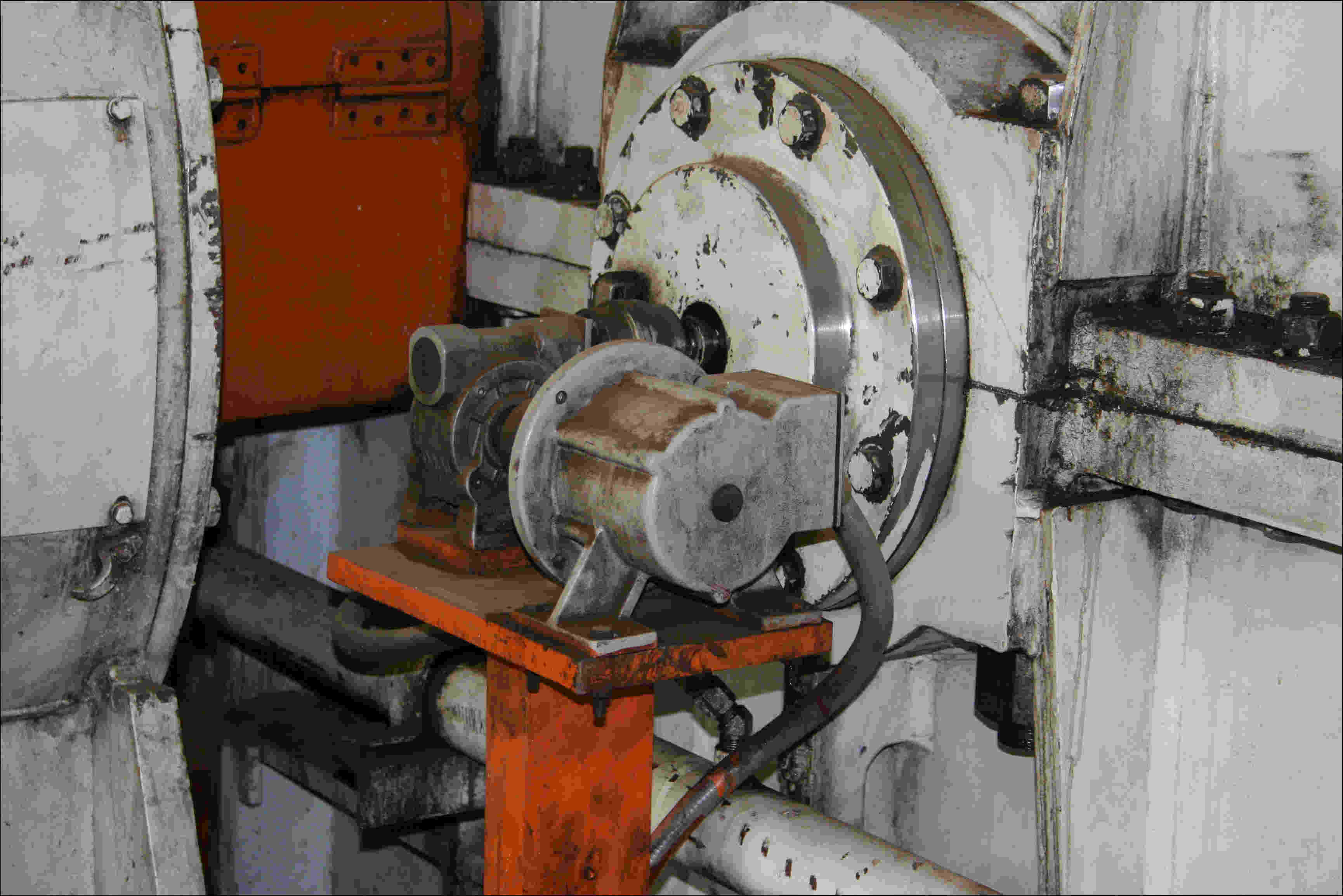

PH2300Mk2 - Boom and Crowd Position Encoding By encoding Hoist, Crowd and Boom positions our systems assist operators during loading, leaving them to concentrate on the operational matters. Ewbank Electrical and Control incorporated, into our systems, the use of resolvers as well as linear displacement sensors, to determine where the dipper and boom positions are. This prevents the dipper from ramming into the sheave wheels or boom belly, resulting in mechanical stresses that will lead to structural damage and failure. The resulting digging envelop ensures that the operator can perform his duties with maximum efficiency. The Taurus System automatically removes the effected motion control from the operator, when a position parameter is exceeded. The component is safely returned to the digging envelope after which control is handed back to the operator to continue with his loading activities. Ewbank Electrical and Control has upgraded the boom position detection and encoding. This monitors the position of the boom to prevent boom jacking and whipping of the suspension rope that results in the unnecessary mechanical impacts, via the A-Frame, into the revolving frame causing structural cracks when not contained. The Taurus System removes control from the operator, reposition the boom safely and then hand control back to the operator to continue loading. The life span of the suspension ropes are dramatically increased as shock loading is limited. |

Boom Position Encoder

Hoist Resolver |

||||||||||||||

|

|

|||||||||||||||

Home : About Us : Services : Case Studies : Contact Us

|

||||||||||||||||