|

|

|||||||||||||||

|

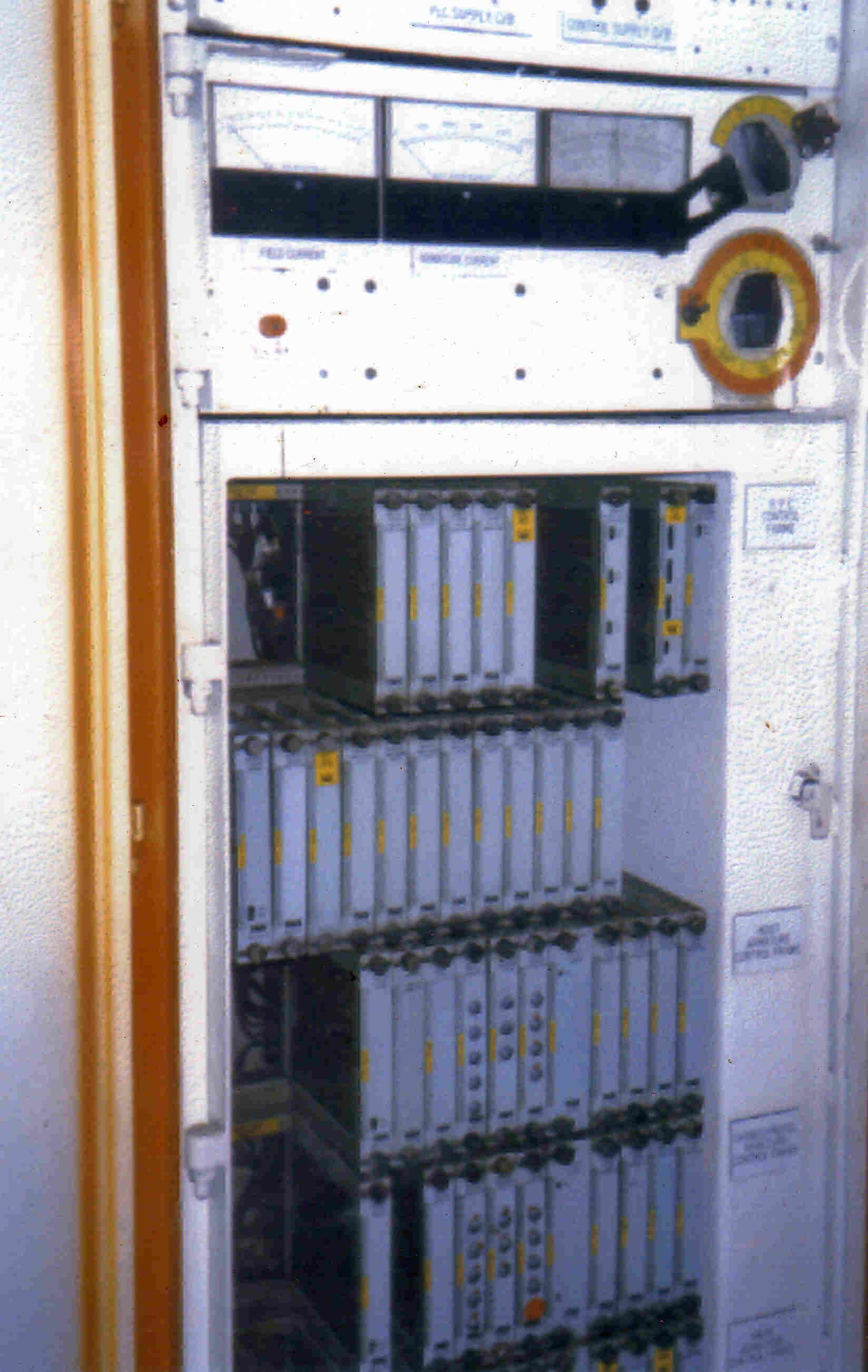

PH2300Mk2 - Relay logics replaced by PLC During the late 90's Ewbank Electrical & Control was commissioned to replace the existing relay logics with a more reliable PLC system. Our customers found that the older relay control system resulted in extended downtime due to an increase in the fault finding time. The request went out to replace the older original relay logic control system with a more reliable PLC system with advanced fault history and fault finding capabilities. Ewbank design, developed and installed an Allen-Bradley SLC500 PLC controlled system with artificial intelligence that replaced the older relay logic system of the machine. Production and technical personnel were now able to monitor real time analog values and machine statuses while the machine worked. Trips and alarms are displayed on the HMI (Human Machine Interface) in the operators coop with drawing reference tags taking the support personnel to the origin of a fault or alarm. A hugh increase in availability was experienced across the shovel fleet. |

Console with HMI

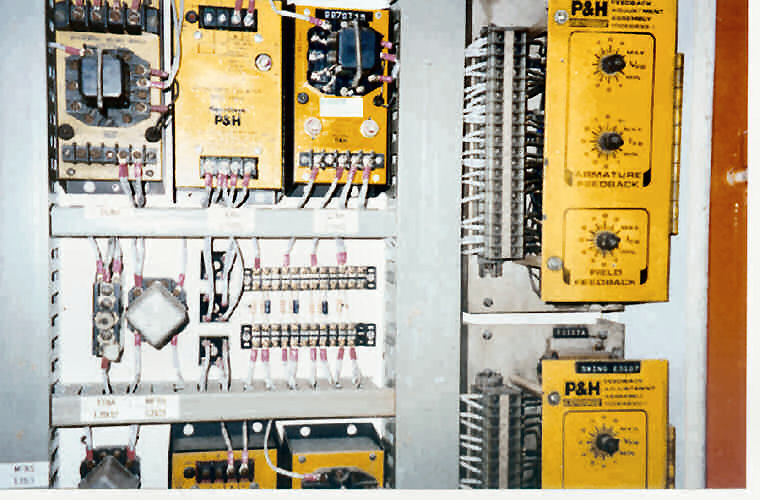

Motion Control Cards |

|||||||||||||

PLC Upgrade |

Upgraded Feedback Panel |

||||||||||||||

|

|

||||||||||||||

Home : About Us : Services : Case Studies :Contact Us

|

|||||||||||||||